ZTA Qws Ceramic Cua sov Element rau DC voltage E-luam yeeb ntaus ntawv

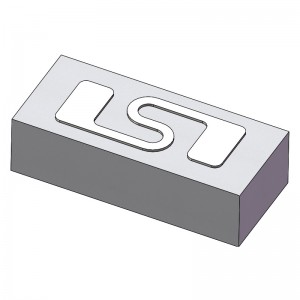

Taw qhia ntawm Keycore III (ZTA)

Internal hollow tsim

Cov khoom siv zironia

Electrode kub kub nyiaj brazing

Lub zog khoov tuaj yeem ncav cuag 15KG. Nws yog peb zaug loj dua lub taub hau zirconia rhaub (rau IQOS) thiab 1.5 npaug loj dua taub hau alumina rhaub.

Kev siv hluav taws xob tsawg, 29% qis dua Keycore I

Cua sov ceev, piv rau alumina Keycore I, nws ceev 7.5 vib nas this mus txog 350 ℃, cua kub ceev nce 1.7 npaug

Flange kub yog tsawg, 30 vib nas this hauv 350degrees, flange kub tsawg dua 100 ℃.

| Txoj kab uas hla | 2.15 ± 0.1 hli |

| Ntev | 19 ± 0.2 hli |

| Cua sov Resistance | (0.6-1.5) ± 0.1Ω |

| Cua sov TCR | 1500 ± 200ppm / ℃ |

| Sensor Resistance | (11-14.5) ± 0.1Ω |

| Sensor TCR | 3500 ± 150ppm / ℃ |

| Lead Soldering Withstand kub | ≤100 ℃ |

| txhuas lub zog tensile | (≥1kg) |

Kev ntsuas qhov ntsuas: qhov ua haujlwm voltage yuav tsum ua kom qhov kub ntawm qhov khoom ncav cuag 350 degrees, thiab tom qab ntawd ntsuas qhov ntsuas kub ntawm flange tom qab 30S ntawm kev ruaj ntseg.

Qhov flange kub ntawm Keycore II (HTCC ZCH) qis dua thaum nws ua haujlwm. Lub flange kub tom qab 30 vib nas this ntawm kev tswj qhov kub ntawm 350 ℃ ntawm qhov ua haujlwm voltage ntawm 3.7v tsis ntau tshaj 100 ℃, thaum lub Keycore kuv nyob ib ncig ntawm 210 ℃ nyob rau hauv tib lub sijhawm.

Ceramic rhaub tau dav siv nyob rau hauv ntau qhov chaw vim lawv cov khoom tshwj xeeb thiab qhov zoo, suav nrog tab sis tsis txwv rau cov hauv qab no:

Muaj cua sov: Ceramic rhaub feem ntau yog siv rau hauv cov khoom siv cua sov hauv kev tsim khoom, xws li yas molding cua sov, roj hmab cua sov, iav cua sov, khoom noj khoom haus cua sov thiab lwm yam teb.

Kev lag luam tshuaj lom neeg: Vim qhov corrosion kuj ntawm cov ntaub ntawv ceramic, ceramic heaters feem ntau yog siv rau cov cua sov corrosive media hauv kev lag luam tshuaj, xws li cua sov ntawm cov kua qaub thiab alkali daws.

Cov cuab yeej kho mob: Ceramic heaters yog siv dav hauv cov khoom siv kho mob, xws li cua sov thiab tshuaj tua kab mob ntawm cov khoom siv kho mob.

Cov khoom siv hauv tsev: Cov khoom siv hluav taws xob ceramic kuj tseem siv tau rau hauv cov khoom siv hauv tsev, xws li hluav taws xob, lub khob hluav taws xob, hluav taws xob pam, thiab lwm yam.

Automotive field: Ceramic heaters kuj siv nyob rau hauv automotive teb, xws li lub rooj zaum cua sov, cav preheating, thiab lwm yam.

Lwm yam kev lag luam: Ceramic heaters kuj siv rau hauv aerospace, tub rog, electronics, semiconductor thiab lwm yam kev lag luam kom tau raws li qhov xav tau cua sov hauv ntau qhov chaw tshwj xeeb.

Feem ntau, cov khoom siv hluav taws xob ceramic yog siv dav hauv kev tsim khoom, kev lag luam tshuaj, kev kho mob, khoom siv hauv tsev, tsheb thiab lwm yam, thiab lawv cov khoom tshwj xeeb ua rau lawv zoo tagnrho rau ntau yam kev xav tau cua sov.